Technology is a staple in the medical and healthcare field. Since the 1950s, it has become a part of various key processes, which include diagnosis, data recording, simulation, and treatments.

Today, medical professionals continue to use and rely on various types of technology to save lives and provide their patients with treatments that improve their quality of life.

Moreover, medical and healthcare experts and practitioners are constantly looking for and discovering technologies to improve and perfect their skills and areas of expertise so they can provide better and more successful treatments. This process includes finding new uses for existing ones and applying them in this field.

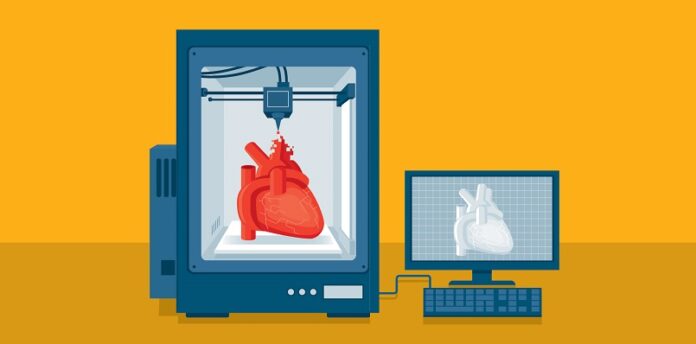

Applications of 3D Printing in Medicine and Healthcare

Three-dimensional or 3D printing is one of the technologies that has found different valuable applications in the field of medicine and healthcare.

3D printing in the UAE, in particular, is not only used in the fields of architecture, engineering, construction, and education. It has multiple applications that have helped and improved various areas of and processes in the medical and healthcare industry.

These remarkable uses include:

1. Production of new medical tools

3D printing has made it faster and more affordable for manufacturers of medical devices and instruments to produce prototypes of their new products. These companies can then use these samples for presentations and testing.

Many manufacturers even use this technology to produce their actual products.

SLA 3D printers require only a few hours to work on a project, that is, depending on the complexity of the product design, to create a medical tool or instrument. If a manufacturer decides to use the traditional production process, it will take them days or even weeks to get their hands on a perfect prototype.

From the smallest medical tools to larger, more complex ones, manufacturers will find it faster and more efficient to use SLA 3D printing to create new medical products.

2. Creation of individualized surgical models

With medical practitioners handling more complex cases by the day, they have to be smarter and more efficient in treating them.

Three-dimensional anatomical models printed using patient scan data are now valuable tools doctors use to provide personalized, precise treatments. With medical and healthcare teams having access to accurate visual elements that they can touch, they can have a better understanding of each patient’s case.

These three-dimensional models can help teams come up with the ideal treatment.

Additionally, 3D printouts can assist doctors in explaining their recommended treatment plan, the processes involved, and benefits to their patients more clearly. This can reduce the patient’s anxieties and encourage them to give their consent faster.

Lastly, an emerging valuable application of 3D tech in the medical field is using it to produce customized surgical tools that are needed for special or unique techniques and cases.

By using biocompatible medical 3D printing materials, medical professionals can create contouring templates, fixation trays, and implant models that can be used for individual patients. These devices enable surgeons to reduce surgery time and boost the accuracy of complex procedures.

3. Prosthetics

One of 3D printing’s most remarkable and valuable uses in medicine and healthcare is the production of prosthetics.

The easy customization and versatility features of 3D printers have made it possible for manufacturers and even practitioners themselves to create individualized prosthetics and implants for patients.

Thanks to this technology, amputees can live a normal life since the hands, arms, or legs they lost can be replaced.

3D printed prosthesis is becoming a more popular option than traditional ones since they are quicker and more affordable to create. Moreover, they can be fully adapted to the body type, disability, habits, and needs of each patient, thanks to 3D scanning and modeling technology.

4. Production of lifelike bones

Aside from prosthesis, SLA 3D printers can create replicas of human bones.

Since this technology can print models with various materials, medical practitioners can produce comfortable bone formations. These can be used to connect the natural bone to the prosthetic.

This increases patient comfort as he or she uses the prosthetic. It helps reduce the risk of injury as well.

Industrial SLAMany 3D printer brands have a large baseplate volume that allows large bones to be printed with accuracy. Aside from using them for connecting prosthesis, doctors can practice on them to prepare for complex operations beforehand.

5. Creation of model dental appliances and prostheses

The dental industry has also benefited greatly from SLA 3D printing technology.

Dentistry practitioners have used SLA 3D printers to produce model and temporary dentures, crowns, bridges, and mouth guards. They have also used the technology to create partial frameworks and guides for dental implants.

Orthodontists can also study SLA 3D printed models to come up with precise and effective treatments for patients with serious dental problems.

Practitioners will find using this technology more cost-efficient and less time-consuming since they do all the processes themselves without having to rely on a contractor to create the models or temporary prostheses.

6. Bioprinting and cellular engineering

3D printing experts from Inoventive 3D say that one of the most innovative applications of this technology in the medical industry is bioprinting.

Researchers are exploring ways to use 3D printers to grow replacement cells, tissues, and even organs in the laboratory for treating injuries and diseases.

Scientists have already succeeded in printing 3D structures with living cells through a technique called in-air microfluidics. This procedure enables the fast production of micro building blocks that help repair damaged tissues.

Through this technique, the damaged tissue can be repaired using the cultured cell material of the patient printed by a specialized 3D printer.

Scientists are also studying the possibility of using 3D printing technology to create patient-specific vascular graft designs and provide testing platforms for new vascular medical devices. These include exploring ways to use it to produce blood vessels that are ready to be implanted into patients.

The production of synthetic blood vessels seems to be a viable study since 3D printing technology can recreate the precise shapes, sizes, and geometries of vessels required by patients. The ability of 3D models to closely match the specific needs of the patient ensures the capillary will be compatible with and function within his or her body.

Since 3D printing technology is constantly being innovated, its applications in the medical and healthcare industry will also continue to grow and expand. These discoveries and uses are worth watching out for.