Is there anything worse than when your blade breaks in the middle of an operation? Or when the cutting result is far below expectations?

If you want to cut, get results are flawless. Learning how to judge the quality of a diamond saw blade is essential. That is why we did all the footwork for you and listed all the critical things to consider when buying.

Check out our ultimate buying guide and discover all details about diamond saw blades. By the end of the article, you will become an expert on the tool. Also, check Austech for quality velcro sanding pads in affordable rates.

Section 1: Do you know the essential components of a diamond saw blade?

If you want to purchase a tool that will perfectly suit your needs, it is vital to know more about its components. When it comes to diamond saw blades.

1.1. We can divide the product across four essential parts:

- Metal core – it is nothing else than a steel disk engineered with precision. It has a rim whose task is to keep the diamonds in place.

- Diamond crystals – these are synthetic, and they have cutting teeth. Their mission is to cut through the materials and do that in a way that meets the user’s expectations.

- Matrix – something needs to hold diamond particles in position, and that is what this metal bond does. It is interesting to note that the diamond particles might lose their efficiency over time.

- Weld – the idea is to connect the core and the components that do the cutting. Soldering or laser welding is the most common option for doing that.

1.2. How Does the Diamond Saw Blade Work?

If you want to know how to judge the quality of a diamond saw blade, you should know more about its working process. It is not difficult to figure out how this tool works. You will notice the surface with the diamonds, which are in charge of the cutting. The cutting process utilizes abrasion to cut through a suitable material for that blade.

The tool does the slicing by rotating the blade at high speed. Over time, the diamonds will lose their sharpness. That is when the matrix comes into play. It releases the crystals that lost their sharpness and put sharp diamonds in their place.

It is interesting to note that you should always keep in mind the matrix’s hardness as it can determine the durability of the blade.

Section 2: For blade type, the complete description

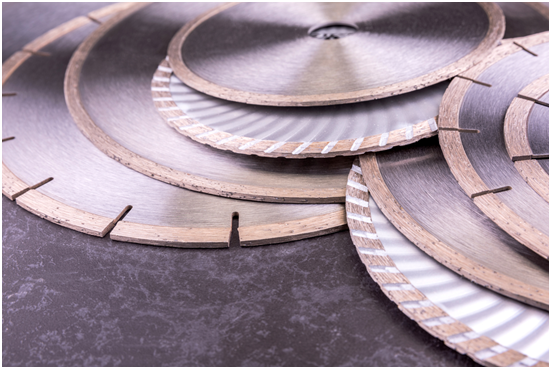

If we are talking about diamond saw blades, you should know it has three common types:

- Segmented blades

- Continuous rim blades

- Turbo blades

It is now time to get to know more about all these types. Take a look below and see which category fits the best. You will notice that the suitability for materials varies, so make sure to choose accordingly.

Segmented Blades

The first type we are focusing on is a segmented blade. When it comes to specifics, you could say that it is relatively versatile. The bonds are either hard or medium, which makes them suitable for dry and wet cutting endeavors.

Although they can handle a wide range of materials, you may still have to face a bit of chipping.

Here is the list of the materials you can use a segmented blade for:

- Granite slabs

- Marble

- Asphalt

- Concrete

- Block

- Brick

The general rule is that these are an excellent choice for materials used in building and construction. If you compare their durability, it seems like they are sturdier than other types. However, this may vary from one unit to another.

You can choose a segmented blade that has a diameter as low as four inches. However, you can also go with 12-inch diameters and bigger. Moreover, it is a large diameter that is commonly present in the market.

When it comes to saws you should match a segmented blade with, consider circular, concrete, and masonry saws.

https://en.wikipedia.org/wiki/Diamond_blade(Diamond saw blade introduction, from Wikipedia)

Section 3: What Are Gullets and Why Are They Important?

Have you ever heard about gullets? Don’t worry if you could use some information on the topic, that is why you came here. Gorges are air spaces located between the tool segments.

Their goal is to assist in heat dissipation, as well as to enhance airflow overall. Additionally, it can help in boosting the performance of the blade by eliminating slurry from the cut.

Gullets come in different shapes and sizes, and they vary depending on the material the operator wants to cut.

You can encounter a vast gorge, which is an excellent choice for cutting asphalt and similar materials. U-shaped gorges are somewhat narrow, and they are more suitable for concrete.

You can also find angled, teardrop, and keyhole gullets. A keyhole gullet can be very versatile while small units can be more suitable for granite and marble. Users should particularly pay attention to how abrasive the material as a full slot can improve heat dissipation.

3.1 Continuous Rim Blades

Let’s take a look at the list of materials that are suitable for constant rim blades:

- Granite

- Porcelain

- Tile

- Glass

- Stone

In other words, if you are cutting materials that are prone to chipping, a blade with a continuous rim is the right choice.

The main difference compared to other types is in those continuous rims and edges. It is an approach they instead use than relying on individual segments.

Wet cutting may be a more suitable option for continuous blades as that will ensure cuts that are chip-free and smooth.

3.2 What Is the Diameter of the Continuous Rim Blades?

The most common dimensions you will encounter vary from four to about 14 diameters. If you are going with a compact-sized blade, you can use it in portable grinders and get a decent performance out of it.

On the other hand, tile and circular saws are a common choice for large-diameter blades.

You can also think about a continuous rim blade with a specific J-slot design. These slots are on the blade’s edges, and their goal is to improve the performance of the module.

By dissipating heat, they extend the life of the blade and improve its durability. In some cases, they can be an excellent option for dry cutting.

3.3 Turbo Blades

You will find these with medium or even soft bonds, which makes them quite versatile and suitable for many applications.

They have one significant difference compared to a continuous rim blade, and that is a serrated edge. The idea is to enable faster cutting without compromising the quality of the cut.

That means you can expect the cut to be smooth even when cutting at high speed. Although it depends on the quality of construction, the basic idea of a turbo blade is to bring the best of both worlds. That is why we can consider it a mix of a continuous and segmented blade.

You can find turbo blades with small diameters, such as four inches. However, it is not often to encounter larger diameters than 12 inches.

Here is the list of materials you can use with this type of blade:

- Granite

- Marble

- Stone

- Tile

- Masonry

it can handle both dry and wet cutting, and you can also try it on other materials used in building and construction.

Section 4: Diamond saw blade manufacturing; you should know

The bond type depends on the manufacturing methods used for the blade. What the bond describes is related to the mixture of diamond and metal. It can be an essential factor in learning how to judge the quality of a diamond saw blade.

You mix the diamonds made of synthetic and metal powder, and then go to manufacture the blade. After forging it, the bond will directly affect which materials can the blade cut.

If the bond is hard, it indicates that the metal matrix has fantastic strength. The deterioration will be slow, especially when compared to soft bonds that may deteriorate relatively quickly. It is only natural for the metal to wear off as you use the saw for cutting.

The general rule is that we want to expose the diamond layers to be able to cur hard materials. That is why you should think in reverse – if you have a soft bond, you can apply it to hard materials. On the other hand, a thick blade is suitable for soft applications.

There are three main types of bond types, and they include:

4.1. Electroplated Bond

The process starts by placing the diamonds in a nickel coating mix. Manufacturers introduce electric current to bind the mixture chemically.

We can expect a blade that is both strong and thin. Thanks to that, it will be ideal for hard materials, especially if you are looking for a high precision cutting level. An electroplated bond is perfect for those who appreciate the aesthetic value of their cuts.

4.2. Vacuum-Brazed Bond

You may notice a usual circular saw that has an outer edge with vacuum-brazed diamonds. Here is how the manufacturing goes – we take a vacuum furnace and use it for welding. The diamond bits then stick to the edge of the metal teeth on the blade.

The main advantage of this method is that it is quite affordable for manufacturers. When it comes to potential applications, soft masonry cutting is an excellent fit for vacuum-brazed bonds.

4.3. Sintered Bond

Did you know this is a technique that the manufacturers most frequently use for diamond saws?

They use incredibly high-pressure levels to press the metal powder and the diamond crystals together. In this case, there is no need to add heat to the process. You can achieve a solid bond by using only pressure.

The material you sintered is now ideal for welding around the steel core and molding into blades. It depends on the quality of the edge, but it should be suitable for moderate and somewhat vigorous materials.

Section 5: About the operation of the saw blade: Wet VS Dry Cutting

You probably noticed that we mentioned dry and wet cutting throughout the article. So, let’s take a moment to consider the difference between wet and dry cutting.

If you are cutting glass, masonry, or hard materials, the chances are there will be particles of fine dust everywhere around you. These particles can be a safety hazard.

Additionally, the friction created when cutting may cause the blade to heat to extreme temperatures. That is why you should avoid using a dry diamond saw wherever possible. It will increase the chances of breaking it.

5.1. Why Should You Run Water Over the Blade?

Water is the way to prevent heat from rising to extreme temperatures. As operating creates friction, water will cool down the cold, and it can also be high in capturing the fine dust we mentioned above.

If you don’t use water, the chances are the blade will be prone to overheating. There is no need to worry about using water. Unlike some other metals, corrosion is not a threat to diamond blades.

However, pay attention if you can put the saw in the water. In case the answer is negative, you can start with dry cutting, but make sure to take the necessary precautions.

That includes:

- ’t inhale fine dust and other particles that may appear in the air when cutting.

Here is an interesting tip on cooling your blade more efficiently. When you are not cutting, keep the saw running. The air will assist in dissipating the heat and cooling the blade down.

Section 6: Other factors when purchasing blades to consider!

6.1. Equipment Compatibility

It is not only about learning how to judge the quality of a diamond saw blade. You also need to ensure that it is compatible with the rest of the equipment used for cutting.

For example, different tools may have different operating speeds and other specifications. The blade you select needs to fit there so that it can perform optimally.

You should avoid buying a blade that can deliver a higher number of rotations per minute than the saw can handle. Similar to that, if you use it at a lower speed than specified for the saw, it may compromise its performance and durability.

6.2. Price and performance ratio

There are two ways you can go when buying a diamond blade. The first one is to find a budget unit that can deliver decent results.

The alternative is to buy a premium tool that may require an additional upfront investment and have higher maintenance costs. However, you will secure a more consistent performance and prolonged lifespan.

The idea is to find the right ratio between price and performance. The tool needs to fit the budget while meeting your expectations in terms of results.

6.3. Durability

It is only natural to want the blade to last as long as possible. You can extend its longevity and performance by sharpening it regularly. Maintenance can also be a crucial factor in extending the lifespan of the tool as long as possible.

Summary:

We hope that you now know how to judge the quality of a diamond saw blade. As we could see in the article, the performance may depend on many factors. Operators need to pay attention that the blade will suit the materials you want to cut. Additionally, you want the blade to fit the saw and the rest of the equipment.

Finally, it is vital for the product to have premium components and top value for money. As long as you use all the information you learned in this article, choosing the best diamond saw blade will be a piece of cake.

If you would like a quality diamond saw blade, please visit our website at https://www.nccuttingtools.com/. We will provide you with the best quality service and products. And you will probably get samples for free.