3D scanning is becoming one of the fastest growing technologies. Right from engineering, aerospace, manufacturing, education, healthcare, 3D scanning is being employed in every area bringing in a host of benefits. According to the latest research reports, the 3D scanning market size is set to exceed USD 10 billion by 2024.

What is 3D Scanning?

3D scanning is a method of scanning the environment or any real-world object to make an accurate replica of the object. With the help of a 3D laser scanning system, 3D shapes are captured and analysed allowing for measurement and collection of data.

There are different types of 3D scanning technologies like Laser Triangulation, Structured Light, Photogrammetry, Laser Pulse based, Contact-based and more. Each comes with its own advantages and limitations.

How do 3D scanners work?

3D laser scanners capture the fine details of the object with accurate point clouds. In this process, the 3D scannersscan the environment, measures the objects using lasers, and creates point clouds which are then transformed into CAD files.

Applications of 3D scanning

Education

Educational institutions across the globe are harnessing the power of technology like smart classrooms, big data, artificial intelligence, virtual reality, augmented reality, etc. 3D scanning is one of the most important elements that help accelerate 3D learning, increase engagement in abstract concepts like topography, body processes, etc, introduce design and engineering concepts in much simpler and interactive ways, and so on. 3D scanners enable students to make interactive 3D models that open up new avenues and enrich their learning experience, especially for STEM concepts.

Architecture

Architects and engineers are using 3D scanning for creating impressive architectural scale models, scanning of archaeological sites for excavation, studying and surveying of construction sites and buildings for restoration projects. 3D scanning is especially used in capturing complex geometries and areas like water constructions, bridges and railways that are difficult to reach. Two of the most commonly used methods are LiDAR and photogrammetry.

In LiDAR, a high-powered laser scanner scans a huge area, including high roof towers covering thousands of dots every second. In the other technique photogrammetry, instead of light, photographs are used to collect the data. Once the pictures are collected, they are imported into the software which then captures data points, calculates the distance and location of each feature in 3D space and then forms a point cloud to create a polygon mesh.

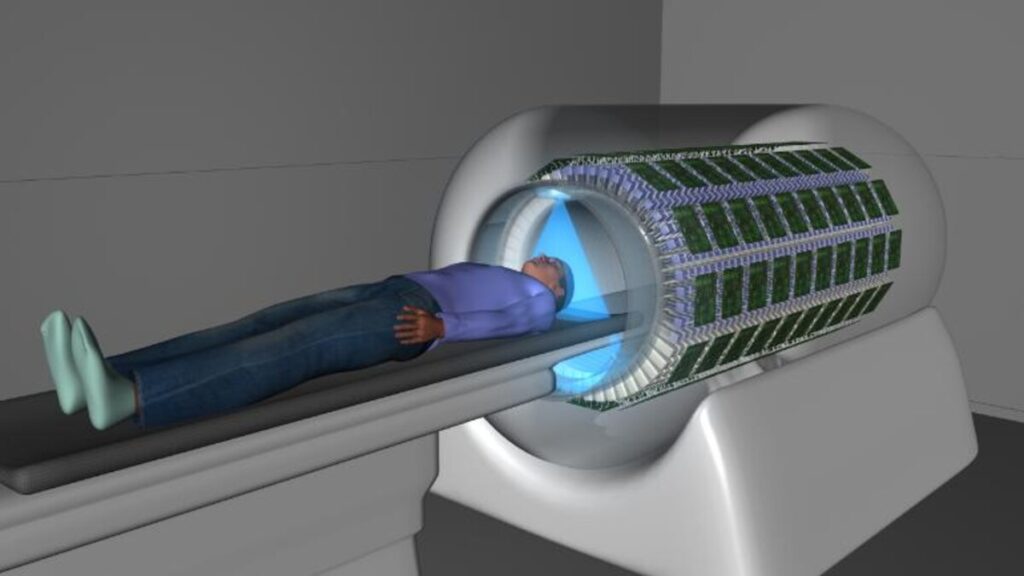

Medicine/Health

With 3D printed knee replacements, skin tissues, bionic ear, elastic bones, etc, already in rage, 3D scanning is also revolutionizing the medical industry. 3D scanners can help doctors visualize, diagnose and study the patient’s body without having to test them directly. Unlike X-rays and MRIs which use harmful radiations to produce the pictures of body parts, 3D scanning is rather a safer procedure. It is faster, accurate and portable. Along with 3D printing, it can be used in the dental industry for producing dentures, crowns, and aligners that perfectly fit within the patient’s jaws.

Industrial Engineering and Designing

In the engineering field, innovative and versatile 3D scanners could be used to capture small objects, complex geometries, and intricate details accurately and precisely. They are useful in every stage like the idea/concept phase, product designing, testing, development, launch, quality control and even aftercare. 3D scanning enhances productivity, accelerates workflow and significantly reduces costly errors. Even in prototyping, physical products can be 3D scanned into digital formats to create prototypes that can then be printed by 3D printers.

Art and History

Artists can bring life to their art and transform it into a commercially viable business through 3D scanning. Opening up new creative opportunities, in 3D scanning, sculptures are scanned to create a replica of the object as a 3D model, it is then exported as an STL file, and then 3D printed.

Benefits of 3D scanning

- Save time in designing work

- Capture intricate details and complex geometries for engineering optimizations

- Ensure parts will fit together on the first try

- Makes the designing and production stages faster with reduced number of prototype cycles

- Helps in maintaining comprehensive quality control. For example, in preserving artifacts 3D scanners can check the compositions of the materials and the volume of the object.

- Light 3D scans help in comparing the original product with the built model. For instance, a piece of jewellery could be cross-checked whether it will fit inside a ring or a pendant.

- 3D reverse engineering is another important advantage.

- 3D surveying is another prime application of 3D laser scanning.