When setting up a new business of circuit boards or as someone who are already an established business into the circuit board industry, you might be on a look out to be PCB manufacturer finding a way to have tons of circuit boards built in no time. Perhaps, you really need countless boards to cater a large segment of clients, but a modest bunch of them are just about enough for a trial run with less production.

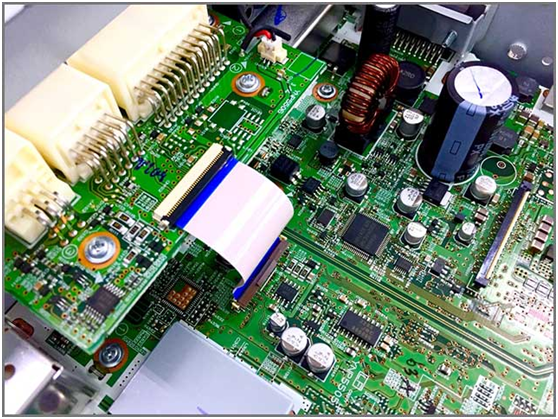

Irrespective of, whether want to kick start with the batch production or want to have trial production, it could be challenging to get it going right off the bat, and this is the time when you need printed circuit boards to come to into play. They are not yet functional until essential components are mounted on the same with the help of PCB designing service to make it functional and working as a printed circuit board assembly (PCBA), and we will know soonwhy it is a preferred option for businesses or clients.

1.Electrical components are already mounted

While working with an expert PCB manufacturer,realize that all the ideal electrical components are already there on the PCB. Not all of theorganizations dealing with PCB are good enough to trust, but trustworthy organizations are those who have been around for some time and used top-notch electrical components for the same rather than using sub-par not guaranteeing that the eventual outcome is desirable.

Normally, you need to be certain that the PCBAs are functioning well or not as per your business needs before you begin to utilize them or sell them. It is always better to consult PCB designing service experts as opposed to attempting to have it all designed and manufactured all by yourself in-house.

2. Blunders can be resolved right at the start

Indeed, even the organizations who have been manufacturing printed circuit boards for quite some time now can even commit errors during their production. A slip-up within the circuit boards production would mean an immense blunder that could cost an organization big tons of cash and instead a printed circuit board assembly (PCBA) helps in PCBA manufacturer in detecting anomalies requiring minor enhancements or product replacement right away.

3. Save a lot monetarily with minimal time invested

Considering how many circuit boards are to be produced it could take a lot of time and efforts to employ individuals to stay ahead of assembling and production needs. Expect big timeinvestment for PCB manufacturer as well to be spent chipping away in manufacturing blank PCBs.

However, PCBAs manufactured with the help of PCB designing service are all worth it with overall cost and time being low. This means PCBAs help to deal with volume with as much low cost possible backed by a quick turnaround time.

4. Assembling appears to be cost effective and timely

Furthermore, consider the assembling going to be timely and cost effective, there is a huge space accessible with PCB manufacturers. Additionally, raw materials are already accessible with PCBA firms helps in cutting down in getting circuit boards as PCBA experts have already got an assembly line in place to deal with the bulk production for you.

5. Efficiency is the biggest perk with PCBAs

One reason that most businesses actually consider PCB designing service is the fact that PCBAs are highly efficient when it comes to working as best parts are brought together operating as a whole when they are joined using welding. When boiling down to a company known for delivering PCBAs in quick time possible, you can tell them exactly the number of PCBs required and the organization will achieve via assembly line.

6. PCBAs are readily available at any point of time

When the printed circuit board production has been finished, a PCB manufacturer can deliver to potential clients in no time. The transportation time can fluctuate, but the manufacturing time is so short that it gets delivered rapidly.

7. PCBAs available for all kinds of business needs

The PCBAs have a macro generic purpose to solve that can be built easily as per specific business needs, wherein one needs to ascertain that the picked option is unquestionably awesome for catering business requirements. Find an opportunity to think about exactly what the PCB designing service offering organization has in store to offer and how quick they can furnish you with the finished boards as both cost and time are crucial variables to serve.

Concluding Thoughts

Now that you find out about the advantages that are related with involving printed circuit board assembly, it is time to find an organization that can furnish with what you want. Ensure that an ideal partner is the one who would endeavor to give you the best help and state-of-the-art PCBAs.

Whether you just need PCBAs for commercial manufacturing or production meaning for a longer period, or merely to test things out for a shorter run, do not disregard the number of PCBAs you are searching for as only an accomplished and experienced firm can get things done for you through an assembly line producing a significant number of boards. Circuit boards have a prominent use in electronics and electrical appliances globally, which means it has to be produced in bulk in a timely manner for organizations worldwide, and that is where PCBAs are instrumental.

Author Bio

With a history going back to 2005, Acme Circuit is the main producer, provider, and exporter of particular, high accuracy, high dependability, high thickness Printed Circuit Boards, otherwise called PCBs. As an organization certified with ISO 9001:2015,it is a company dedicatedly focused on sticking to industry norms in both planning and assembling of PCBs, to offer a one-stop answer for all client prerequisites right from PCB design going way up to assembling PCBs and fabricating them in turn.