An industrial air purifier is a specialized air filtration system which passes the air quality testing designed for use in large commercial and industrial settings to improve air quality by removing various contaminants and particulate matter from the air. These systems are typically much larger and more powerful than residential air purifiers to accommodate the higher air volumes and more significant pollutant levels found in industrial environments.

Key features and functions of industrial air purifiers may include:

- High Airflow: Industrial air purifiers are equipped with powerful fans and large filters to process a high volume of air, ensuring efficient purification.

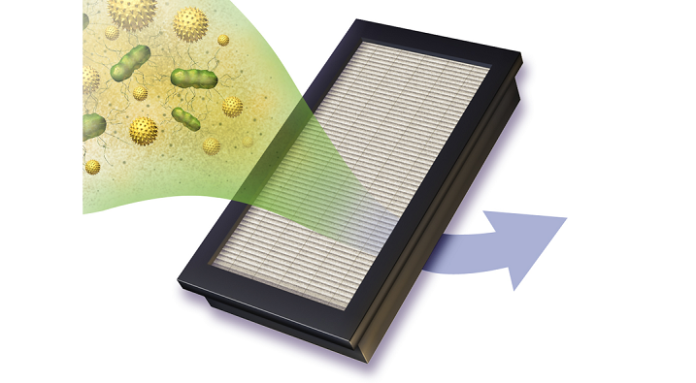

- Multiple Filtration Stages: They often employ multiple filtration stages, including pre-filters, HEPA (High-Efficiency Particulate Air) filters, activated carbon filters, and sometimes specialized filters for specific pollutants.

- Removal of Various Contaminants: Industrial air purifiers can remove a wide range of contaminants, including dust, particulate matter, pollen, mold spores, bacteria, viruses, volatile organic compounds (VOCs), and gases like sulfur dioxide or ammonia, depending on the specific filtration media used.

- Continuous Operation: Many industrial air purifiers are designed for continuous operation to maintain air quality in industrial spaces where pollutants are generated continuously.

- Customization: They may offer customizable features to adapt to the specific needs of the industrial environment, such as variable fan speeds, timer settings, and air quality sensors.

- Ducted Systems: Some industrial air purifiers are integrated into the building’s HVAC (heating, ventilation, and air conditioning) system, allowing for whole-building air purification.

Use cases for industrial air purifiers

Industrial air purifiers are commonly used in manufacturing facilities, warehouses, laboratories, cleanrooms, healthcare settings, and other environments where air quality is critical for the health and safety of workers, product quality, or research outcomes. They help mitigate health risks associated with exposure to airborne contaminants and ensure compliance with air quality regulations.

When selecting an industrial air purifier, it’s essential to consider the specific contaminants present in the environment and choose a system with the appropriate filtration capabilities to address those concerns effectively. Additionally, regular maintenance and filter replacement are essential to ensure the continued effectiveness of these systems.

What is CO2 adsorber filter?

A CO2 adsorbers, also known as a carbon dioxide adsorption filter or CO2 scrubber, is a device designed to remove carbon dioxide (CO2) from the air or gas stream through a process called adsorption. CO2 adsorption is the adhesion of CO2 molecules onto the surface of a solid material, typically activated carbon or another adsorbent material. This technology is commonly used in various applications where the removal of CO2 from the air or gas is necessary.

CO2 Adsorber filter use cases

- Industrial Processes: CO2 adsorber filters are used in industrial applications, such as natural gas processing, biogas purification, and chemical manufacturing, to capture CO2 emissions and produce cleaner gases.

- Environmental Control: In closed environments like spacecraft, submarines, or sealed buildings, CO2 levels can rise to unsafe levels. CO2 adsorber filters help maintain breathable air by removing excess CO2.

- Greenhouses: In controlled agricultural environments like greenhouses, CO2 is sometimes added to enhance plant growth. CO2 adsorber filters can help regulate and maintain optimal CO2 levels.

- Scuba Diving: CO2 scrubbers are used in closed-circuit rebreathers worn by scuba divers. These devices remove exhaled CO2 to allow the diver to recycle and breathe the same air, making diving safer and more efficient.

- Carbon Capture and Storage (CCS): In the context of combating climate change, CO2 adsorption technology is employed to capture CO2 emissions from power plants and industrial processes, preventing them from entering the atmosphere.

Typically, CO2 adsorber filters consist of a container filled with adsorbent material. Air or gas containing CO2 is passed through this material, where CO2 molecules adhere to the surface of the adsorbent. Once the adsorbent becomes saturated with CO2, it can be regenerated by removing the CO2, allowing the filter to be reused.

Activated carbon is a common adsorbent material due to its high surface area and porosity, which provide ample sites for CO2 adsorption. Other materials, such as zeolites, amine solutions, or specialized CO2-selective adsorbents, may also be used depending on the specific application.

CO2 adsorber filters play a vital role in various industries and technologies, contributing to cleaner air, reduced greenhouse gas emissions, and improved safety in closed environments.