Traditional PCB design and assembly can be a long process that involves several vendors and manufacturers. With all of the steps and involved vendors, traditional PCB assembly can be fraught with problems. Instead of hoping that your order is filled on time, why not look to turnkey PCB assembly for quick turnaround time.

With speedy turnkey PCB assembly, one manufacturer handles the entire process from design to assembly to shipping.

Quick Design Approval

Turnkey PCB design relies on cloud-based files to speed up the manufacturing process. Instead of waiting for a designer to draft the board, customers can upload their designs so the manufacturer can provide an immediate quote.

In the traditional process:

The design is sent back and forth from the designer to the customer, taking weeks for approval.

With an instant upload, the customer has already approved the design. If the manufacturer has to tweak it, they can share the design changes through a cloud-based file, thus speeding the lines of communication.

In House Vendor Orders

Traditional PCB processes include ordering parts and supplies from multiple vendors. With turnkey assembly, an in-house expert uses one vendor and can quickly order necessary supplies.

There is no need to coordinate between different companies, so there is no worry about parts that don’t fit. In-house supply coordinators have developed relationships with vendors and know who can deliver parts the fastest.

Useful For Small Businesses and Small Orders

Since turnkey PCB assembly involves personalized production, the single-channel steps can be applied to any size order, even minimum orders for small businesses. Supplies can be ordered in any amount and they do not need to meet vendor quotas; the prices are what they are, no matter the number.

Errors are Found and Resolved Quickly

Because the entire process is done in-house, any problems that arise can be quickly fixed. This speeds up the process because the problems are found in the earliest stages.

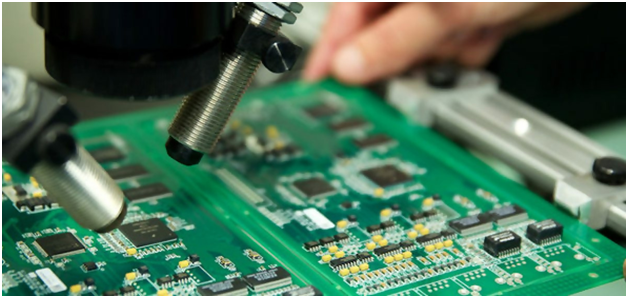

The manufacturer reviews the design, then purchases, assembles, tests, and packages the PCBs, so any problems will arise are quickly dealt with before the product moves too far through the process.

Fewer errors happen with turnkey PCB manufacturing because so few people are involved. Ironically, the faster service through a single channel provides a better product than the slower, traditional manufacturing process.

Consistency Improves

The goal of any PCB manufacturer is to build a consistent, top quality board. Clients who work with turnkey PCB manufacturers are happier with their PCBs than those who work with traditional manufacturers.

Turnkey manufacturers still design prototypes for clients, but they do it quickly and with fewer errors. To get the PCB to the client quickly, they have to be able to move through the design-to-assembly process without issues. Turnkey manufacturers have mastered the process.

Why Turnkey PCB Manufacturing

Saving time and money are two good reasons to give turnkey PCB manufacturing a try. It might seem like it isn’t possible, but turnkey manufacturers have perfected the in-house process. With fewer production channels, the process speeds up, errors decline, and customers are happy.