If you want to invest in conveyor belts for the industrial handling of materials, you may be daunted by the different types on the market. It is important to get one that suits your company’s needs because the right belt can increase your profit margin and streamline the assembly line. But you need to know the basic conveyor types so you can know how they match your business needs.

Basic Conveyor Belts

The following are basic beltings and their applications:

1. Roller Bed

This type consists of rollers for different production requirements like required speed or product weight. Shorter belts in this category have only two rollers, but if you want to increase the belt distance, you need to add more rollers. The setup is good for conveying items over a long distance because it reduces friction, making it easy for the items to move smoothly.

The applications include transporting, inspecting, assembling, sorting, and packing items. You can typically find it in an airport baggage section and postal sorting office. You can visit this website to know the important specifications for conveyor systems.

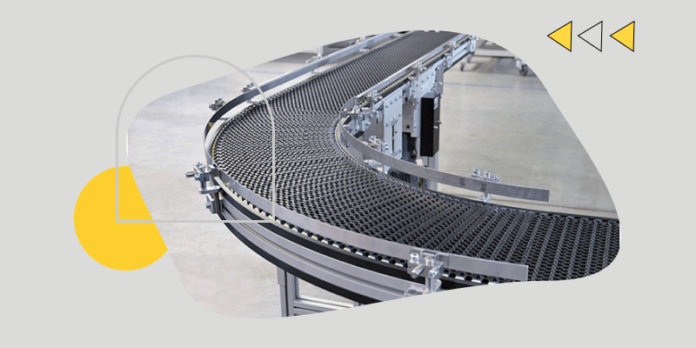

2. Curved Belt

Its frame is curved to enable it to move products around corners or maximize the available space in a factory. The belt can curve up to 180 degrees. It is usually used in baggage handling offices to change the conveying direction of an item.

3. Decline/Incline Belt

It has a gear motor, center drive, and double or single nose take-up. Its surface is rough to enable it to carry items up or bring them down. You can use it to convey products to any elevation while preventing them from dropping. Additionally, you can use it to boost a gravity flow system.

4. Wash-down Conveyor

If you have seen where donuts are made, you may already know this type. Pharmaceutical, food, and beverage industries often use harsh chemicals to wash and sterilize as part of their safety guidelines. Wash-down or sanitary conveyors are built to withstand sanitary procedures.

The systemis rugged and not difficult to clean. It can convey items that come directly from freezers or furnaces. In addition, food industry equipment must be able to run through the glaze, hot oil, or bread. Because a larger wash-down conveyor with a flat wire belt can handle both greasy and wet items, it is suitable for offloading bulk goods such as crates and oil drums from ships.

Modular vs Flat Belts

Each type of belt has a specific strength and ideal use. Among the different types of conveyors, modular and flat belts are widely used. One of them may just be the ideal option for your business. Let us see their characteristics and benefits.

Flat Belt Conveyor

When people talk about conveyor belts, they are referring to flat belt conveyors. The system is typically driven by friction and is ideal for handling medium or light loads. But there is one that specifically handles heavy-duty tasks. Its construction and design are simple, which makes it easy to integrate into an already existing system.

It is useful for conveying items internally, that is, within an organization or factory. It uses a set of pulleys to drive a continuous belt, which may consist of synthetic fabric (nylon or polyester) or natural material. You can use it to convey soft or small items or objects that are irregularlyshaped.

Furthermore, a flat belt conveyor can provide friction for applications that require inclining. This is especially when a steel or smoother plastic belt may lead to increased sliding or slipping of materials. The downside of this belt is that when it becomes damaged, you need to replace it completely.

Benefits of Using a Flat Belt System

- It is ideal for long-distance.

- It is durable, flexible, affordable, and simple.

- It can withstand heavy load.

- It gives a smooth operation.

- It requires less maintenance and repair.

- It is very economical.

Modular Conveyor Belt

It has interlocking segments that allow you to replace any segment that breaks or damages instead of the entire segment. This helps you to save costs over the life span of the equipment. However, you should prepare to pay a high initial cost to get the system.

The system can carry heavy loads compared to most flat conveyors. It is ideal for applications that require sterile handling since the segments are easy to clean and sanitize. It also does not harbor bacteria or retains liquid.

If you want a conveyor for pharmaceutical, food, and beverage applications, a modular type is ideal. You can visit https://beltingedge.com/plastic-modular-belting to read more about the modular belting system.

Benefits of Using a Modular Conveyor Belt

- It is suitable for transporting items around curves and bends.

- It is easy to repair and extend if necessary.

- Cleaning is easy as you can simply hose down to get rid of dirt.

- It is versatile as it allows declining and inclining at various speeds.

- It can transport various dry or wet food products.

- It can transport cold or hot products.

Conclusion

Choosing a belting system is like choosing a suitable tire for your vehicle. Snacks, baked food, and other items in an assembly line travel on different surfaces like the curved, roller bed, flat, and modular belts. Some are ideal for a specific purpose; others suit different applications, but they all guarantee a smooth operation. However, you should choose one that suits your business needs. And always check out for quality and cost effective conveyor belt suppliers if you want smooth operating experience in your unit.