According to a report published by Grand View Research, Inc., the Internet of Things (IoT) market accounted for USD 605.69 billion in 2014. Increasing investments, technological proliferation, and increasing internet connectivity are likely to propel the growth of the market over the next few years.

Internet of Things is used to connect several devices in order to ease data sharing and operations among peers and are adopted in various applications with machine learning technologies and advanced analytics. Rapid adoption of artificial intelligence along with increasing need for data handling are also driving the IoT market.

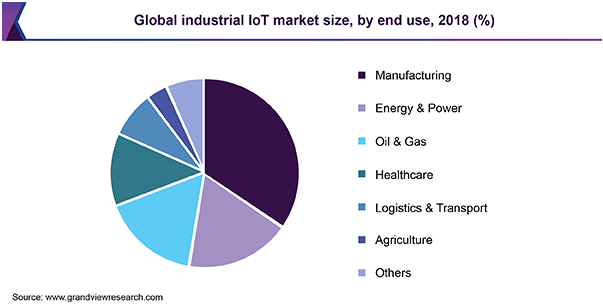

Manufacturing is expected to emerge as the main consumer of the technology particularly in end use industries over the years. IoT platforms enable data transfer through various connected devices, however, the manufacturers are increasingly inclined to promote wireless connectivity. IoT can also prevent major disruptions and sense initial signs of breakdown by using predictive maintenance and help in preventing unexpected downtime in industrial systems. IoT is improving the efficiency and reducing expenses in internal operations, which is a strategic requirement for manufacturing companies as it can help offer more value to the customers.

IoT has various advantages such as improving workforce service and productivity, reduce maintenance costs, and save energy costs, with applications in workshops, automobiles, and home automation. It is prominently adopted in manufacturing operational intelligence, enabling asset monitoring, remote servicing, and predictive maintenance. Government initiatives and recent innovations by major companies are anticipated to fuel the adoption of IoT technology globally.

Favorable FDI policies along with various government schemes such as Make in India, Made in China 2025,Industry 4.0,Industrial Value Chain Initiative (IVI) in Japan, andSmart Cities Mission in India,are promoting the adoption of digital technologies across the industrial sector. Government initiative in Germany called ‘Industrie 4.0’ is aimed at smart automation, incorporating autonomous and decentralized production,and data exchange in manufacturing technologies.In January 2017, The European Commission has announced the Horizon 2020 Research and Innovation program for co-funding IoT pilots with a contribution of EUR 100 million.

The adoption of IoTin manufacturing offers an opportunity to automate many of the complex processes along with monitoring and providing asolution. This is due to its applications in industrial sector as the IoTtechnology is used for data handling, business analytics,cloud services, and improving the industrial processes.

How is Manufacturing Sector Benefiting from IoT Market?

IOT provides various features and characteristics that can be used to maximize and enhance manufacturing. Some of the prominent features and characteristics of IoT are:

- Tracking Tools &Fixtures

Lack of tools or misplacement causes delays in the workflow, negatively affecting the completion and shipping process. Many factories and plants have to rely on important tools for their daily operations and sometimes also have to use government furnished equipment (GFE), which is an accountability for that equipment. This is where the ability to track such fixtures can help the manufacturers.

The IOT technology provides various work-in-progress tracking tools for manufacturers that track the components to be integrated and build large or complex assets. Barcode scanning is also used to track work in progress in many cases but it does not enable quick access of a missing part. It can also be useful in determining the wrong area to solve the issue along with avoiding wasted expense of actively tracking down misplaced parts.

- Cold Chain Monitoring

IoT technology is used to ensure products that require pre-determined temperature range are handled properly and stay the temperature limit. It ensures quality storage, creation, and shipping process for temperature sensitive goods. Cold chain monitoring also helps to track the perishable products, eatables using descriptive, predictive, and real time analytics to provide requirement based solutions.

- Process Automation

With the advent of IoT, digital transformation has promoted productivity in organizations leading to simplified management processes. Companies wanting to expand their profit margins face the challenge of creating innovative systems. Industrial Internet of Things (IIoT) provides assistance by bringing more efficiency in systems and making the process of product promotion flexible and affordable.

IoTenabled industrial automation can offer integration of various commercial technologies across major industrial applications, such as programmable logic controllers (PLCs).Increasing cost effective technologies are being used in operations and maintenance since theyconsist of sensors, intelligent controls, and smart switches. This is due to the requirement in industries that need systems for determining projected servicing time using predictive analysis.Organizations are keen to integrate robotics, machinery, and human power to reduce operational efforts and manufacturing costs.

Internet of Things is used in products and services in the form of computing devices,cloud based engineering,sensors, and gateways for process automation. For low voltage motors,some smart sensor are being developed that can be used to provide wireless condition monitoring data. The devices can also be used with third party motors to transmit information. It can also generate number of alerts regularly when motors perform sub-optimally. Emerson Process Management has introduced new wireless andlow cost sensors that can turn enormous amount of data into useful information.

Conclusion

The IoT market is witnessing high demand due to its ability of improving efficiency and enabling new services. IoT connects industrial devices, equipment, and consumer electronics,enabling information transfer and device management, which also helps improve and optimize processes in manufacturing industry. Many organizations and companies are taking advantage of the technology to increase productivity and efficiency. It is also being used to gain a deeper insight to customers’ behavior patterns and needs. Workers under taking IoT training along with trained experts will benefit companies to expand their interests toward a better future. Companies are inclined to invest in IoT and R&D in order to gain advantage for expanding globally to strengthen their market presence. Some of the major companies operating in the market are Accenture PLC; Alcatel-Lucent; Google Inc.;General Electric; Samsung Electronics; Apple Inc.; Free scale Semiconductors;IBM; and SAP SE.

Company Bio:

Grand View Research, Inc. is a U.S. based market research and consulting company, registered in the State of California and headquartered in San Francisco. The company provides syndicated research reports, customized research reports, and consulting services. To help clients make informed business decisions, we offer market intelligence studies ensuring relevant and fact-based research across a range of industries, from technology to chemicals, materials and healthcare.